Virtual Sampling: Reducing Waste in Design & Product Development

In today’s fast-paced world, the fashion industry is constantly evolving, seeking new solutions and creative ways to reduce waste and improve efficiency in design and product development. An innovation that has gained significant traction in the 2020s is virtual sampling. This blog will explore the concept of virtual sampling, its benefits, and how it is revolutionizing the traditional design and product development process in the apparel industry.

KEY TAKEAWAYS

- Virtual sampling significantly reduces the waste and costs associated with physical samples.

- It allows for faster iterations and improvements in the design process.

- Virtual sampling contributes to sustainability by minimizing the environmental impact of physical sample production.

- Digital fabrics created in SEDDI Textura provide a realistic representation of the final product.

- Lack of skills in 3D design processes can be a barrier to adopting virtual sampling.

Could Physical Samples Be a Thing of the Past Soon for Apparel?

The fashion industry has long relied on the traditional method of physical sampling to finalize designs before production. However, this manual and lengthy process is not only costly, but also contributes to significant waste. With virtual sampling, designers can eliminate the need for multiple physical prototypes. This shift could potentially make sole reliance on physical samples a thing of the past, as virtual sampling provides companies with a more efficient and sustainable alternative.

What is Virtual Sampling?

Virtual sampling is a revolutionary process that allows designers to create and test their designs in a digital environment. This approach uses advanced software to create accurate representations of designs, providing designers with a clear and realistic view of how the final product will look. Virtual sampling is transforming the fashion industry, offering a more efficient, cost-effective, and sustainable alternative to traditional physical sampling.

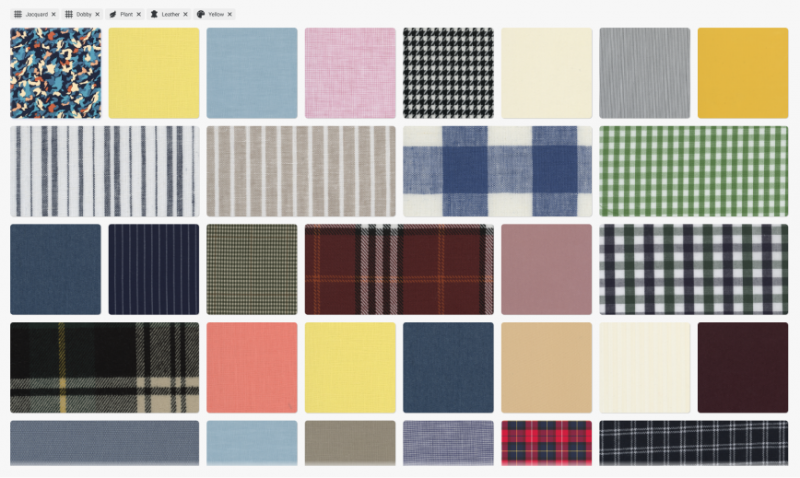

Seddi Textura Fabric Library

What are Digital Fabrics?

Digital fabrics are realistic representations of physical fabrics, that are created using advanced technology and software. These digital fabrics can be used in virtual sampling to test different fabrics, colors, and styles in a digital environment, without the need for physical fabric samples. Companies like SEDDI, with its product SEDDI Textura, are at the forefront of this technology, providing designers, brands, and suppliers with the ability to digitize a wide range of fabrics. This innovation is creating positive change in the fashion industry, by reducing waste, increasing the ability to meet market demand, and offering a more sustainable alternative to traditional fabric sampling.

What Does 3D Virtual Sampling Mean for Business and the Environment?

Businesses can also save on costs associated with producing physical samples. At the same time, virtual 3d sampling reduces the environmental impact of the fashion industry by minimizing waste and the carbon footprint generated by the production and transportation of physical product samples. This shift towards a more sustainable approach is not only beneficial for the environment, but also aligns with the growing consumer demand for eco-friendly manufacturing processes and products.

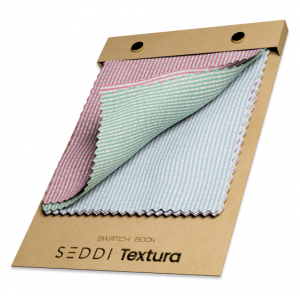

Quality That’s Close to the Real Deal

The quality of virtual fabric samples has improved significantly in recent years thanks to advancements in technology. Today, virtual samples, like those created in programs like SEDDI Textura, are almost indistinguishable from their physical counterparts, providing designers with an accurate representation of the final product. This level of quality is essential for designers to make informed decisions about their designs and ensure that the final products are accurate, and meet expectations.

How Digital Fabrics Created in SEDDI Textura Solve Digital and Physical Needs

How Digital Fabrics Created in SEDDI Textura Solve Digital and Physical Needs

SEDDI Textura is at the forefront of digital fabric creation, making it possible to create realistic 3d virtual representations of fabrics that can be used in virtual sampling, with just a desktop scanner and a computer browser. Designers can now test different fabrics, colors, patterns and styles in the cloud, saving time and resources.

Benefits of Virtual Sampling

The benefits of virtual sampling are numerous. In addition to reducing waste and costs, virtual sampling allows for faster iterations and improvements in the design and manufacturing process. This speed ultimately leads to a better final product, as designers can make informed decisions about their designs in a shorter amount of time. Furthermore, the traditional design and product development process in the apparel industry is known for being time-consuming and wasteful. Virtual sampling contributes to sustainability by minimizing the environmental impact of physical sample production.

Lack of Skills to Implement 3D Design Processes

While virtual sampling offers numerous business benefits, one of the challenges is the lack of skills among designers to use 3D design processes. This can be a barrier to adopting virtual sampling solutions, as designers need to be proficient in using 3D design software to create accurate and realistic virtual samples. However, with the increasing availability of training materials and resources, this barrier is gradually being overcome. Additionally, many universities and institutions around the world are now offering 3D design courses and certifications, ensuring that the next wave of talent entering the industry will be equipped to move digital product creation processes forward.

Overcoming the Learning Curve

While virtual sampling offers numerous benefits, there is a learning curve associated with adopting new technology. Designers and companies must invest time and resources into training and development to fully leverage the potential of virtual sampling. This lengthy process includes understanding the software, tools, and processes involved in creating virtual samples. However, the long-term benefits far outweigh the initial investment, as virtual sampling can significantly reduce costs and improve efficiency.

The Future of Virtual Sampling

As technology continues to evolve, the future of virtual sampling looks promising. With advancements in artificial intelligence and machine learning, virtual samples will become even more realistic, providing designers, manufacturers, brands, and apparel companies with an even more accurate representation of the final product. Additionally, virtual sampling will become more accessible, with more designers and businesses adopting this innovative approach to design and product development.

The Impact on Small Businesses and Independent Designers

Virtual sampling is not just for large fashion brands and companies. Small businesses and independent designers can also benefit from this innovative approach to design and product development. By reducing the costs associated with producing physical samples, virtual sampling provides a more affordable option for small businesses, brands and independent designers to bring their designs to life. This democratization of the design and production process is essential for fostering innovation and creativity in the fashion industry.

The Impact on the Supply Chain

Virtual sampling has the potential to revolutionize the supply chain in the fashion industry. By replacing physical samples with digital ones, companies can streamline their operations, reduce shipping costs, and minimize the environmental impact of transportation. Additionally, when there are disruptions to physical supply chains, digital supply chain processes can continue forward, reducing the impact of world events and physical delays on production cycles.

The Role of Artificial Intelligence in Virtual Sampling

Artificial intelligence (AI) is set to play a significant role in the future of virtual sampling. With advancements in AI, virtual samples will become even more realistic, providing designers with an accurate representation of the structure of the structure and final product. SEDDI Textura is the first product to leverage AI for textile digitization. The platform’s cloud-native AI engine is trained with physical textile appearance and property data to construct trustworthy 3D simulations from desktop scanner images of fabrics. Another exciting use case for AI is that it. can also be used to analyze and optimize designs, further improving the efficiency and effectiveness of the design process.

The Global Impact of Virtual Sampling

Virtual sampling has the potential to have a global impact on the fashion industry. By using sampling costs and reducing the need for physical samples, virtual sampling can help to minimize the environmental impact of the fashion industry worldwide. This shift towards a more sustainable approach to design, manufacturing, and product development is essential for addressing the global challenges of climate change and environmental degradation.

FAQs

- Q: What is virtual sampling? A: Virtual sampling is the process of creating and testing designs in a digital environment, eliminating the need for physical prototypes.

- Q: How does virtual sampling contribute to sustainability? A: Virtual sampling minimizes the environmental impact of physical sample production by reducing waste and the carbon footprint associated with the production and transportation of physical samples.

- Q: What is SEDDI Textura? A: SEDDI Textura is a technology that makes it possible for anyone to create digital fabrics easily, quickly, and accurately with just a desktop scanner and the SEDDI Textura platform.

- Q: What are the challenges of adopting virtual sampling? A: One of the main challenges is the lack of skills among designers to use 3D design processes, which are essential for creating accurate and realistic virtual samples.