‘Fashion moves fast’ and fashion designers must move even faster to design and produce the garments we see in stores. As a fashion designer with a deadline approaching everything becomes a race against the clock. You need to deliver a fully realized collection of garments that your customers will want to buy, at a price that will make a profit. And you have to deliver NOW or the garments won’t make it to stores in time and your customers will go to the competition.

During these busy periods, often called ‘Design Time’, your best intentions of keeping a calm, zen workspace are quickly shattered. You find yourself buried in a mountain of fabric swatches, reference samples, buttons, zippers, color swatches and threads. You are rushing from your desk with the newest sketches to the presentation room to quickly pin them on the wall; only to have your boss tell you to redo half of them in the next 10 min before the meeting with the creative director.

In this process of creative iteration many fabrics are proposed and discarded until the garments are finalized. I’ve heard stories of creative directors asking someone in the room to remove their sweater or jacket and pinning it to the wall to use as the fabric for a new style. Meanwhile a fabric that has been in development for months is discarded, never to be used.

Once the bosses have finally made up their minds you, the designer, have to translate this mess of fabrics and sketches into ‘techpacks’ that the manufacturer can use to build the actual garments. And, in true fashion form, this needs to be done for the whole collection in two weeks or the garments won’t make it to stores on time.

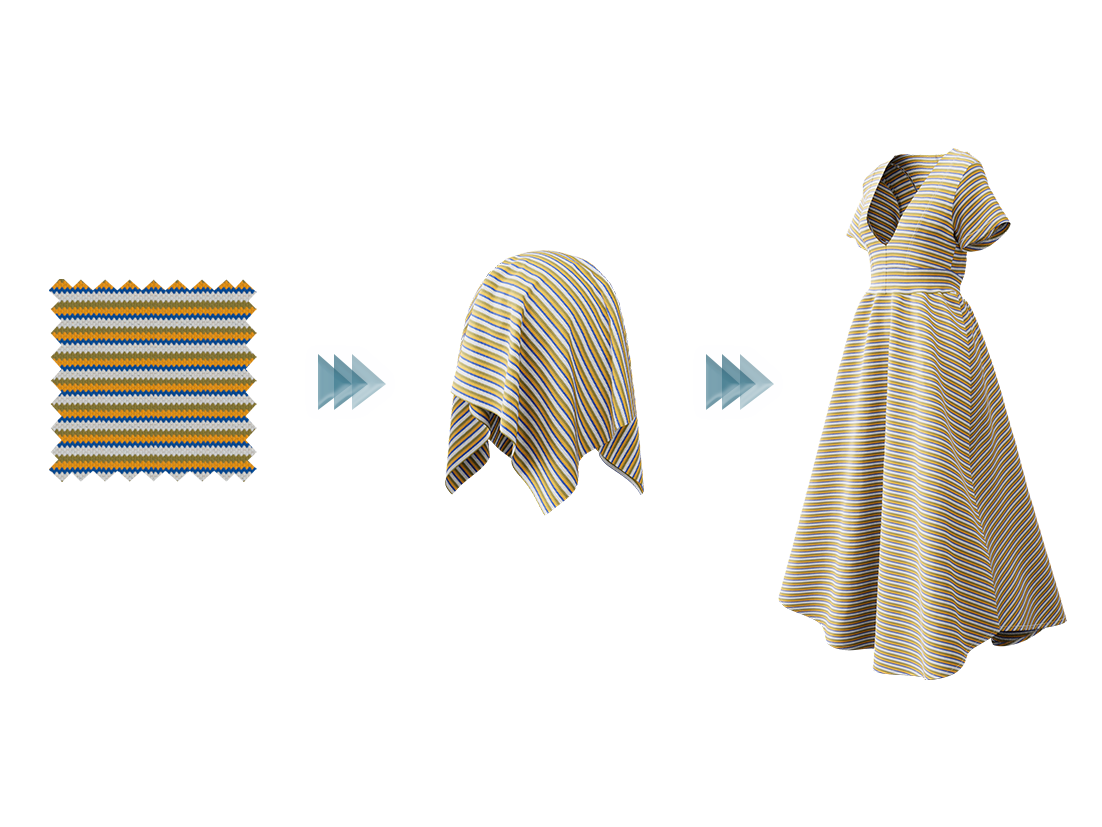

In recent years 3D design software has emerged as a tool to design faster and relieve some of the pressure of the design process. The 3D garment created during design is more accurate than a sketch on paper so the garment should be able to be directly handed off to the manufacturer without lots of rework to translate the fantasy sketch to reality.

However, 3D design is limited today by the availability of digital fabrics. Turning a physical fabric into digital (digitalizing) requires capturing and expressing two important aspects of the fabric: its visual appearance and its drape. Today this requires shipping a yard of fabric to two separate scanning services, one for visual, one for drape, and waiting up to a week to receive the result. Other brands have purchased the expensive machinery and hired more staff to digitalize fabrics themselves. Because digitalization of fabrics is so cost prohibitive, both in time and money, the potential of 3D design is being stifled.

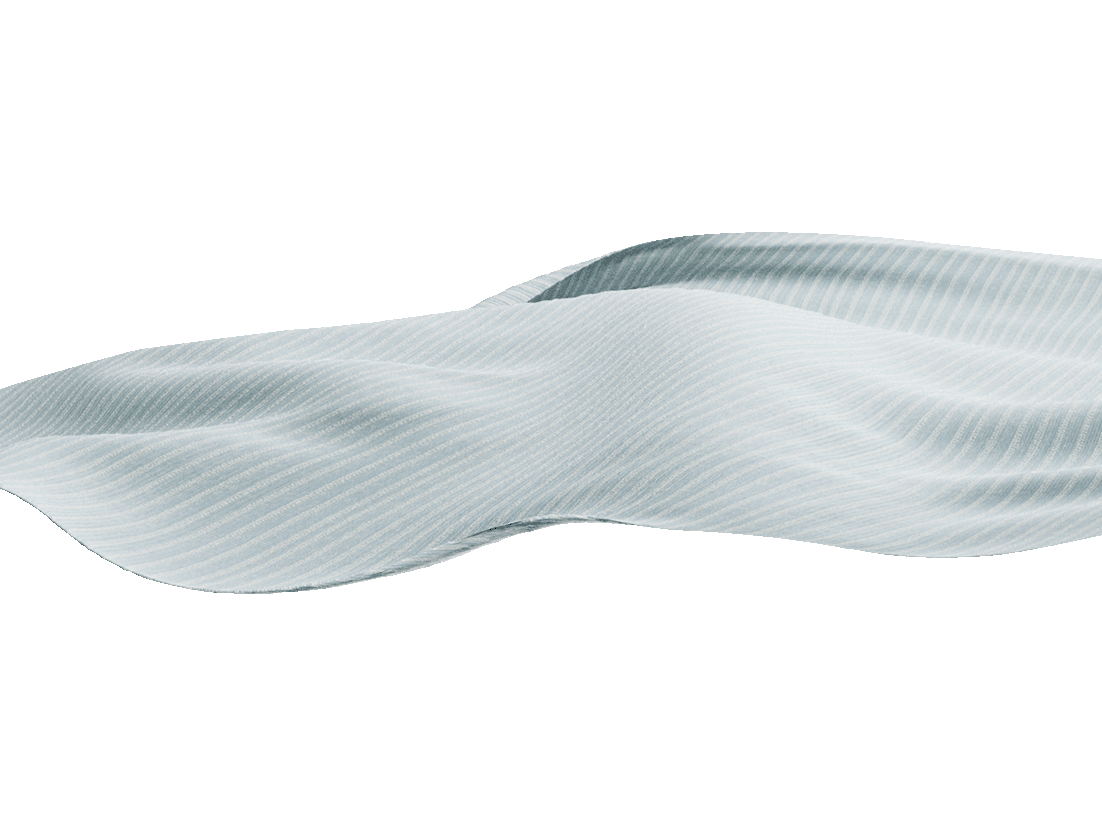

Textura is addressing the problem of digitalizing fabrics from a new angle. Instead of shipping fabric or buying expensive machinery, designers can use a regular flatbed scanner to make a single scan of the fabric, upload it to the Textura website and get the results back in less than 24hrs. The designer receives a complete digital fabric with both visual and drape properties, ready for use in any 3D software.

Textura is addressing the problem of digitalizing fabrics from a new angle. Instead of shipping fabric or buying expensive machinery, designers can use a regular flatbed scanner to make a single scan of the fabric, upload it to the Textura website and get the results back in less than 24hrs. The designer receives a complete digital fabric with both visual and drape properties, ready for use in any 3D software.

So the next time that the creative director changes their mind at the last minute you can be ready to react and build a 3D design just as fast.